Published on Jan. 28, 2025

Efficient Use of Labor in Pig Production

Farms are becoming larger and more efficient, with increased access to technology. However, finding staff remains a significant challenge across the industry. This situation has compelled the sector to focus on labor management and efficiency, which are critical components for maximizing profitability in pig production. At Hypor, we recognize that success lies not only in improving productivity but also in enhancing overall pig quality, the social behavior of sows, and their ability to “do the job by their own”. This approach allows producers to utilize labor more effectively, leading to better outcomes throughout the production system.

Labor Efficiency: A Key to System Profitability

Some swine barns produce pigs with significantly less labor and frustration than others. Recent insights indicate that 87% of production outcomes are influenced by staff attitude, while only 13% is attributed to technical skills1. In pig production, success isn’t about breaking production records—it’s about maximizing total system profitability. Although there is a positive correlation between production levels and financial returns, studies have shown that only 40% of economic performance differences can be explained by the number of weaned pigs per sow per year2. While productivity is important, the quality of pigs significantly impacts final performance.

The number of employees or the hours worked cannot be determined solely based on number of animals. It is also influenced by factors such as the production system adopted, management strategies, and expected productivity3, among others such as cultural or educational factors. As so, the worker-to-sow ratio can vary significantly, for example, from 1:350 to 1:400 in northwest Europe, to 1:100 or less in Latin America or East and Southeast Asia.

Larger farms, primarily managed by hired labor, may be able to implement management practices like extending the hours dedicated to sows during farrowing or allocating more labor to specific areas, such as gilt development. For instance, managing a farrowing room with 20 crates takes less time per sow than a room with only 10 crates.

Many farms struggle with labor shortages, primarily due to availability. Thus, optimizing staff efficiency is crucial. Factors that influence labor efficiency include daily work routines, barn layout, distance between buildings (older operations that have expanded through modifications face greater challenges), production flow (for smaller herds, producers can optimize labor efficiency by weaning sows every 2nd, 3rd, or even 5th week instead of every week), the level of automation (feeding, washing, environmental control, etc.), and the amount of required maintenance.

Labor demands

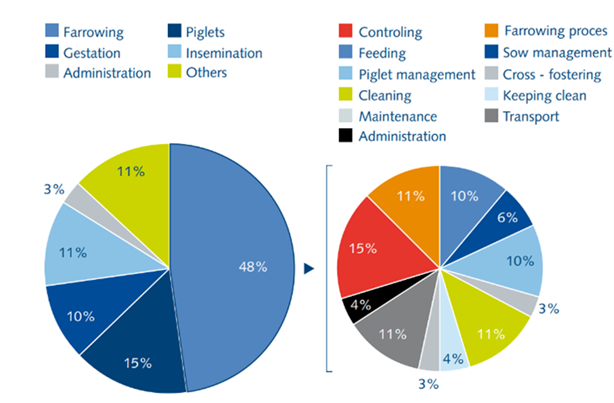

Managing sows involves a lengthy to-do list. From detecting estrus to getting sows bred, and from loading sows into farrowing to making sure sows are eating well in lactation, there are many opportunities to improve management practices and efficiencies. Approximately 50% of labor demand in pig farming occurs in the farrowing house (Figure 1), driven by factors such as the farrowing process, piglet care, and general management practices. As the farms achieve higher total pigs born, the stillborn rate and pre-weaning mortality often increase. If a farm can have someone attend sows in the farrowing area for 18 hours a day, with two shifts, about 85% of the farrowing can be monitored.

However, in most cases this is not feasible. Therefore, measuring key metrics such as piglet birth weights, stillborn rates, and losses in farrowing crates is essential for improving pig quality and, consequently, labor requirements. Improved piglet quality and uniformity also help reduce labor demands in the nursery, which is the second most labor-intensive area in sow farming, following the farrowing unit.

It is crucial to shift the mindset from merely increasing performance to optimizing it through more efficient and sustainable cost-of-production strategies4. Producers should focus on aspects that genuinely make a difference. For instance, by monitoring temperatures on heat mats and investing in pre-farrow nutritional strategies, we can shorten farrowing duration and reduce the need for constant attendance during this critical period. By saving labor in these areas, we can ensure better oversight of each sow on a daily basis.

Producers need to adapt management strategies to accommodate labor constraints while also responding to societal demands for more group housing, reduced antibiotic use, and strengthened biosecurity protocols5. For instance, breeding gilts at the right age and weight and keeping them in optimal body condition from the start will increase lifetime performance, retention rate, and she’ll probably require less maintenance to do her job, which is raising quality pigs.

How to Improve Efficiency on the Farm

Automatization

The pursuit of improved efficiency has led to significant advancements in on-farm data technologies. With smartphone-enabled data input and access, as well as sensors for precise bin readings, data-centric solutions are shaping the future of swine management. However, experts agree that no matter how advanced, machines will not replace skilled managers or animal handlers. Instead, these tools serve as invaluable aids, allowing farmers to manage their workforce more effectively and enhance herd performance6.

One notable development is the use of automatic feeders, which significantly contribute to operational efficiency. These systems can dispense feed accurately at scheduled intervals or in response to animal behavior, optimizing nutrition while minimizing waste. Beyond convenience, the precision of automatic feeders improves feed conversion ratios and growth performance, both crucial for farm profitability. Additionally, these feeders reduce labor demands, enabling workers to focus on higher-skill tasks such as monitoring animal health, managing breeding, and ensuring welfare standards. By alleviating physical strain and minimizing the risk of human error, automatic feeders create better working conditions. They eliminate guesswork by delivering exact portions of feed at precise times, ensuring that pigs receive the right amount of nutrition. This automated precision supports a seamless workflow, allowing farm staff to optimize schedules to meet both human and animal needs7.

For these reasons, investing in automated feeding systems, along with ventilation solutions, should be a top priority for enhancing farm performance and animal welfare.

Further efficiency gains can be achieved through innovations such as installing high-pressure plumbing lines with quick-disconnect fittings in each room, which save time compared to dragging portable units across the barn. While hot-water systems may involve higher installation and operating costs, they offer superior cleaning capabilities. For instance, pre-soaking barn areas for 30 minutes significantly reduces washing time.

Farms with a higher degree of automation require fewer staff compared to those with minimal mechanization. Advanced technologies, including sensors, play a critical role in managing farm operations. For example, computers equipped with machine learning algorithms can reliably detect lameness by analyzing livestock gait patterns. These systems can also monitor abnormal behavior, detect estrus, track temperature fluctuations, and even follow the farrowing process with precision.

By embracing these innovations, farms can enhance operational efficiency, improve animal welfare, and reduce labor demands, paving the way for a more sustainable and productive future.

Managing Turnover and Optimizing Processes

Employee turnover is a significant challenge for swine farms. High annual turnover rates are often linked to less trained and less efficient staff, leading to increased hiring needs, higher costs, and decreased overall productivity. Moreover, hiring unsuitable candidates can exacerbate these issues, resulting in lower herd productivity, employee dissatisfaction, and increased labor expenses. Effective long-term employee management requires comprehensive, integrated programs that address both staff quality and quantity. A farm’s ability to meet budgeted and targeted performance levels is intrinsically tied to its workforce. Farms that achieve strong performance do so because of their people. As one expert aptly puts it: "Pigs do not achieve excellence; people achieve excellence through their pigs"8.

It's important to have complete list of all tasks to be completed by day of the week, and knowing the time it takes to complete each task. To improve time and resource management, which can help reduce turnover and enhance operational efficiency, consider implementing the following strategies:

- Daily Swine Work Log: Borrowing a technique from industry time management consultants, farms can ask employees to log how they spend their time over a two-week period. Analyzing these logs can reveal which tasks consume excessive time, highlighting opportunities to streamline workflows

- Barn Layout Map: Creating a map of the barn and overlaying employees’ chore routes can shed light on inefficiencies, such as unnecessary backtracking. This visualization can inform adjustments to chore routes or even renovations to optimize the workspace.

- Detailed Work Routines: Developing clear, written daily work routines challenges both management and employees to analyze every action taken. These routines often highlight opportunities to adjust practices or physical features of the barn for better efficiency. Additionally, written routines ensure continuity during vacations or emergencies. For example, specifying the location of the main water shut-off valve prepares staff for unexpected situations9.

The Importance of a Motivated Team

Maintaining a motivated, cohesive team requires deliberate effort over time. Farms staffed with engaged individuals, who share a commitment to producing excellence, tend to outperform others. Recognizing and addressing inefficiencies—whether related to staff turnover, workflow, or barn design—enhances both employee satisfaction and farm profitability. By focusing on effective workforce management and systematic approaches, farms can lower employee turnover, enhance job satisfaction, and achieve long-term operational success.

The power of genetics

Advances in genetics are transforming livestock production, leading to significant improvements in efficiency, profitability, and animal welfare. Hypor piglets demonstrate outstanding early growth potential, with an average birth weight of 1.5 kg. This advantage is enhanced by a considerably lower percentage of piglets weighing less than 1,000 grams compared to competitors. These improvements reduce the challenges associated with rearing low-weight piglets and enhance overall efficiency in managing litters. Additionally, the high quality and uniformity of Hypor piglets also result in fewer interventions needed during the farrowing and nursery phases. This not only reduces labor demands but also promotes better overall health and accelerated growth rates, yielding superior performance across all production metrics.

Efficient management of the sow herd is a critical component of Hypor's success. To maximize weaning capacity and overall profitability, Hypor employs advanced breeding techniques that integrate phenotypic and behavioral data into the breeding value. This innovative approach produces strong, easy-to-manage sows that perform well independently of the housing system. By focusing on genetic excellence, Hypor reduces the labor required for herd management, resulting in substantial cost savings while boosting overall productivity.

Conclusion

Efficient labor use in pig production is no longer just a competitive advantage, it is a necessity. With labor shortages, rising production costs, and evolving societal demands, producers must adopt innovative strategies to optimize their workforce and enhance operational performance.

The integration of advanced technologies, such as automation and data-driven tools, plays a pivotal role in reducing labor demands while improving productivity, animal welfare, and worker satisfaction. Complementary strategies, including detailed workflow analysis and employee management programs, further support the efficient allocation of resources and foster a motivated, cohesive team.

Moreover, genetic advancements continue to redefine the industry by delivering robust, easy-to-manage sows and uniform, high-quality piglets that require less intervention. By combining genetics with sustainable labor practices, producers can achieve a harmonious balance between productivity and efficiency, securing long-term profitability.

Ultimately, the future of pig production lies in embracing innovation, optimizing labor efficiency, and nurturing a motivated workforce—proving that the right people, practices, and technologies can transform challenges into opportunities for growth and success.

References

- Voce Magazine, April 2022 Edition.

- Dr. K. Töller and Dr. M. Knees.

- Alves, Laya Kannan & Gameiro, Augusto & Schinckel, Allan & Pospissil Garbossa, Cesar Augusto. (2022). Development of a Swine Production Cost Calculation Model. Animals. 12. 2229.

- https://www.porkbusiness.com/news/hog-production/6-trends-watch-maximize-sow-farm-labor-resources

- https://www.porkbusiness.com/news/hog-production/6-trends-watch-maximize-sow-farm-labor-resources

- https://www.canr.msu.edu/news/can-precision-livestock-farming-help-optimize-farm-labor

- https://www.barnworld.com/feeders/the-role-of-automatic-feeders-in-reducing-labor-on-pig-farms

- https://swine.extension.org/swine-human-resources-managing-employees/#Staffing_Farms

- Pork Information Gateway Factsheets, Efficient Employee Management, Swan, Michael, April 2011.