Published on June 14, 2024

Japfa-Hypor farm remains disease-free for over a decade

NOTE: This article was originally published in Asian Pork Magazine and has been republished here with permission.

Farms in Vietnam saw costs swell due to disease preventive measures. But the 12-year-old farm in Binh Phuoc province, Vietnam jointly owned by Hypor Vietnam and Japfa Comfeed managed to keep diseases out without additional costs, writes HA THU, Regional Correspondent and Assistant Editor at Asian Pork Magazine,

Their secret is the BioHypor program. “it is a compendium of best practices that are precisely and consistently implemented," Mark Anthony Mercado, Technical Support Manager at Hypor East & Southeast Asia, told Asian Pork Magazine.

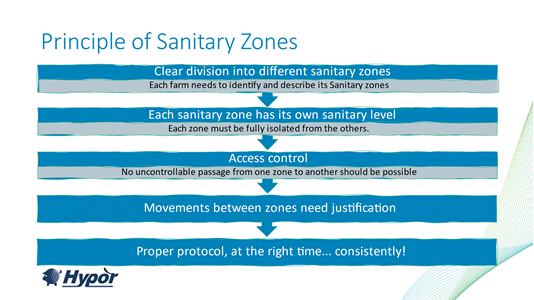

Dr Mercado emphasized the three biosecurity principles: zoning, people, and consistency. Although many are familiar with these three factors, the BioHypor program has several small details that make a difference in performance.

Why do zones fail?

The Hypor-Japfa farm follows a three-zone biosecurity system - a private dirty zone, an intermediate clean zone, and a restricted production area- with strict control over access to each zone.

"The zones must be physically separated with safety nets or walls." These structures restrict personnel, trucks, and equipment to designated zones, preventing access to unauthorized areas. He stressed that farms must ensure there is no 'shortcut' or hole in the walls. These must be high enough so that people cannot jump over them.

Dr Mercado said breaches often occur when farms do not have properly separated zones. "These breaches often happen, even on farms equipped with cameras and other surveillance systems." He stressed that having three zones is fundamental, and strict decontamination procedures before entering each zone are crucial.

"For the zones to work, ensure proper downtime, cleaning and disinfection, and shower procedures/ facilities. More often than not, I find shower rooms without water, and people forget to change their clothes and footwear. All the equipment is a waste of money if no one follows procedures."

Ensuring compliance

"It's human nature to look for the easy way, hence the shortcuts," said Dr Mercado. To avoid this, Japfa's farm managers emphasize the risk of disease outbreaks if farm workers become lax. But simply making them understand the principles is not enough; they must see the benefits of keeping the animals healthy and the farm safe.

Regular performance checks are necessary. "Don't just listen to what workers claim. See if they are walking the talk," Dr Mercado advised. He added that regular training will help farm workers focus on and consistently perform their tasks.

"Efficient money is money well spent. These methods will help farms avoid unnecessary biosecurity breaches and maximize biosecurity investments," concluded Dr Mercado.

Does automation help?

Automation offers tools for farms to minimize the impact of human errors, and for the Japfa-Hypor farm, it addresses labor supply issues.

"People can make mistakes such as wrong dosing, incorrect execution of protocols, or late diagnosis of clinical issues. These mistakes can lead to heavy economic losses," said Wouter Deley, Senior Veterinarian and Health Manager of Hendrix Genetics Breeding Division.

Still, he advises farms considering automated equipment to be well-prepared when automation fails. "You need a trained person to maintain/ repair the equipment and have spare parts available. Most importantly, have a plan B to maintain biosecurity while automation gets fixed.”

Keeping safe amid high disease pressure

Having a disease-free status may lead to neglected biosecurity. This is true for old farms that have never had an outbreak. However, the biggest concern for old farms is the accumulation of pathogens over time. This accumulation and a few human 'mistakes' could lead to an outbreak.

"Not all mistakes in biosecurity lead to a pathogen's introgression. Most of the time, we are just lucky that nothing happens. However, as pathogen pressure rises, the chances of problems and failures also increase," said Dr Deley, adding that regular health checks should be done to monitor the status of farms.

"We must be aware of existing diseases and when they normally occur," he told Asian Pork Magazine, adding that gathering this information is necessary to ensure that animals perform at optimum levels.

These checks also enable a quick response in the event of disease challenges and help design a cost-effective vaccination and medication program.

Early training helps

The earlier farm workers become aware of biosecurity, the better. In October 2023, Hypor Vietnam and Japfa Comfeed cooperated with Nang Lam University, Ho Chi Minh City, on a workshop to raise biosecurity awareness among students. It was attended by teachers and students of the animal health department and Japfa Comfeed's farm workers.

"Universities are valuable partners in any disease eradication project because they train the next generation of professionals. Thus, they influence the mindset of these students as they enter the profession," said Dr Deley.

However, universities often lack practical experience. Collaboration between companies like Hypor Vietnam and universities is crucial to provide future workers with expertise, knowledge, and practical experience.

Disease resilience is possible, and the Hypor-Japfa farm is proof of this. "Biosecurity systems need not be expensive nor complicated. We have proven that an old farm like ours can remain safe with a simple yet effective mindset: consistently applying biosecurity measures. Other farms can too," concluded Dr Mercado.